The meat packaging industry and its primary marketplace have witnessed significant consolidation over the years, which in-turn, produced an oligopoly environment. Competition has been intense and, for the most part, has been in the form of continuous price reductions. In particular, the cellulose casing industry has faced increased spending requirements needed to address significant environmental challenges created by the manufacturing processes. The resulting financial strain has suppressed most technological innovations.

APorous has identified this innovation gap and has developed a cost efficient solution with real technological advances. Breathable porous polyolefin and Nylon films are designed to allow the heat seal packaging, smoke permeation and cook-in of the meat products. The new packaging film is low cost, without the cellulose casing manufacturing environmental pollution. The new product features high smoke permeation, high MVTR, flavor and color impregnation, heat seal-able, flexible and lower cost.

Another application of the breathable films is fresh produce and fruit packaging. Fresh produce are living plants, they will remain fresh when the natural biological metabolism is maintained. Cooling of the produce slows down the metabolism rate, but the produce still absorbs oxygen to break down carbohydrates and releases water and carbon dioxide as by-products.

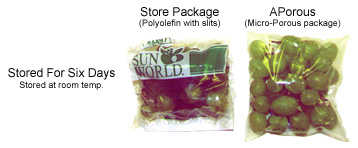

The APorous breathable package is specially formulated to keep the fruits dry, avoid fogging of the packaging and allows water vapor egress, oxygen and carbon dioxide exchange through the packaging. The hermetic packaging also inhibits pest, bacterial, pathogen infestation, as well as fungal ingress. The film has demonstrated to prolong the shelf life of fresh vegetable by as much as three times.

Breathable film prolongs grape shelf life by three times.

The original store package allowed pest ingress and mold infestation.